2024-01-02 13:09:42

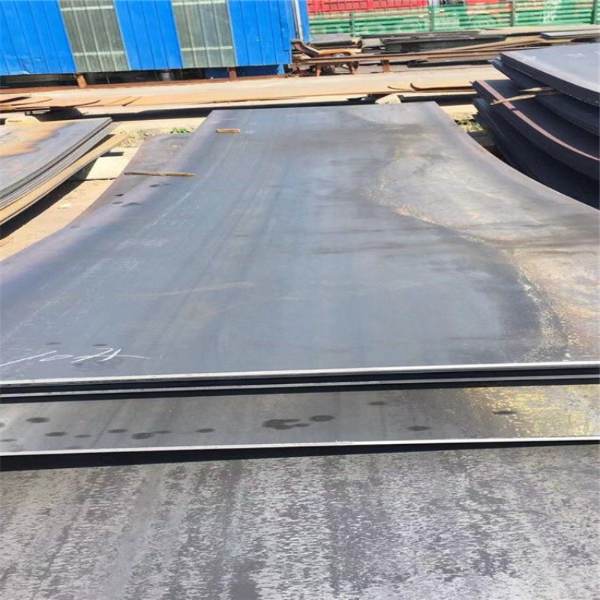

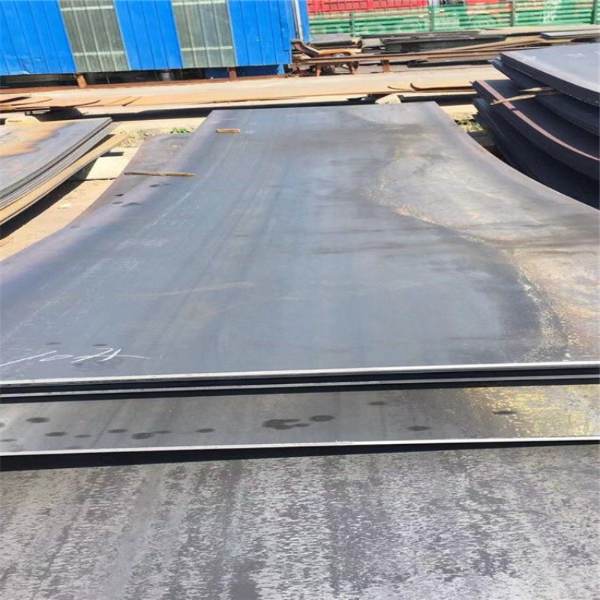

Is Cold Rolled Steel Plate Rebar

Abstract:

In this article, we will explore the world of cold rolled steel plate rebar. Cold rolled steel plate rebar is a type of reinforcement steel that has undergone a cold rolling process to improve its strength and durability. This article aims to provide readers with an in-depth understanding of the characteristics, benefits, and applications of cold rolled steel plate rebar.

Introduction:

Cold rolled steel plate rebar has become increasingly popular in construction and engineering industries due to its superior mechanical properties and cost-effectiveness. This article will discuss the four key aspects of cold rolled steel plate rebar, namely its manufacturing process, structural properties, advantages and disadvantages, and applications. By delving into these topics, readers will gain a comprehensive knowledge of this material and its potential uses in various fields.

1. Manufacturing Process:

The manufacturing process of cold rolled steel plate rebar involves several stages. Firstly, hot rolled steel coils are produced from molten steel using a continuous casting process. These coils are then subjected to a series of processes, including pickling, cold rolling, annealing, temper rolling, and skin-passing. Each step contributes to the final quality and characteristics of the cold rolled steel plate rebar. It is essential to understand these processes to comprehend the superior properties of this product.

1.1 Pickling:

During the pickling process, the hot rolled steel coils are cleaned using acid to remove impurities such as rust, scale, and oxides. This step prepares the surface of the steel for subsequent processes, ensuring a smooth and uniform finish.

1.2 Cold Rolling:

After pickling, the steel coils undergo cold rolling, where they are passed through a set of rollers at room temperature. This process compresses and elongates the steel, resulting in a thinner and stronger material. Cold rolling also improves the surface finish and dimensional accuracy of the steel.

1.3  Annealing:

Annealing:

Annealing is a critical step in the manufacturing process. After cold rolling, the steel coils are heated to a specific temperature and then slowly cooled. This heat treatment process relieves internal stresses and enhances the steel's mechanical properties, such as ductility and toughness.

1.4 Temper Rolling:

Temper rolling involves passing the annealed steel through a series of rollers to achieve the desired level of hardness and strength. This process further improves the material's dimensional stability and surface quality.

1.5 Skin-Passing:

Skin-passing is the final step in the manufacturing process, where the steel undergoes cold rolling once again with a small reduction in thickness. This process provides a smooth and uniform surface finish, making the steel plate rebar suitable for various applications.

2. Structural Properties:

Cold rolled steel plate rebar exhibits exceptional mechanical properties, making it an ideal material for reinforcement purposes. The cold rolling process imparts several characteristics to the steel, including increased strength, improved surface finish, enhanced dimensional accuracy, and better formability. These properties enable cold rolled steel plate rebar to resist bending, cracking, and other deformations, making it highly suitable for load-bearing structures.

2.1 Strength:

Cold rolled steel plate rebar offers higher tensile strength and yield strength compared to hot rolled rebar. This increased strength allows for better load-bearing capacity, ensuring the structural integrity of buildings and infrastructure.

2.2 Surface Finish:

The cold rolling process results in a smooth and uniform surface finish, free from defects and imperfections. This feature enhances the bond between concrete and the rebar, providing greater structural stability and reducing the risk of corrosion.

2.3 Dimensional Accuracy:

Cold rolled steel plate rebar exhibits excellent dimensional accuracy, ensuring consistent and precise reinforcement in construction projects. This feature contributes to the overall quality and reliability of the structure.

2.4 Formability:

Cold rolled steel plate rebar possesses good formability, enabling it to be easily bent, shaped, and fabricated to meet specific design requirements. This flexibility allows for versatile applications in different construction projects.

3. Advantages and Disadvantages:

Like any material, cold rolled steel plate rebar has its advantages and disadvantages. Understanding these aspects is crucial in determining whether this material is suitable for specific applications.

3.1 Advantages:

- Superior strength and durability, ensuring long-term structural stability.

- Excellent surface finish, promoting strong bond with concrete and preventing corrosion.

- Improved dimensional accuracy, ensuring precise reinforcement.

- Good formability, allowing for versatile applications.

- Cost-effective compared to other types of reinforcement steel.

3.2 Disadvantages:

- The cold rolling process increases production costs compared to hot rolled rebar.

- Requires specialized equipment and facilities for manufacturing.

- Limited availability and fewer manufacturer options compared to hot rolled rebar.

4. Applications:

Cold rolled steel plate rebar finds applications in various construction and engineering projects due to its superior properties and cost-effectiveness.

4.1 High-rise Buildings:

The exceptional strength and durability of cold rolled steel plate rebar make it ideal for high-rise buildings. It provides the necessary reinforcement to withstand heavy loads and seismic forces, ensuring the structural integrity of the entire building.

4.2 Infrastructure Projects:

Infrastructure projects such as bridges, highways, and tunnels require reinforcement elements that can withstand extreme conditions and loads. Cold rolled steel plate rebar offers the necessary strength, dimensional accuracy, and corrosion resistance for such projects.

4.3 Industrial Structures:

Industrial structures often face challenging conditions, including heavy machinery, chemicals, and fluctuating temperatures. Cold rolled steel plate rebar's superior mechanical properties and corrosion resistance make it suitable for reinforcing industrial structures.

Conclusion:

In conclusion, cold rolled steel plate rebar is a highly versatile and effective material for reinforcement purposes. Its manufacturing process, structural properties, advantages, and applications have been explored in detail in this article. By understanding the unique characteristics of cold rolled steel plate rebar, engineers, contractors, and construction professionals can make informed decisions regarding its implementation in various projects. The continuous advancements in the production and application of cold rolled steel plate rebar have opened up new possibilities in the field of construction and engineering. Further research and innovation in this area are necessary to unlock the full potential of this remarkable material.