2023-12-31 13:56:46

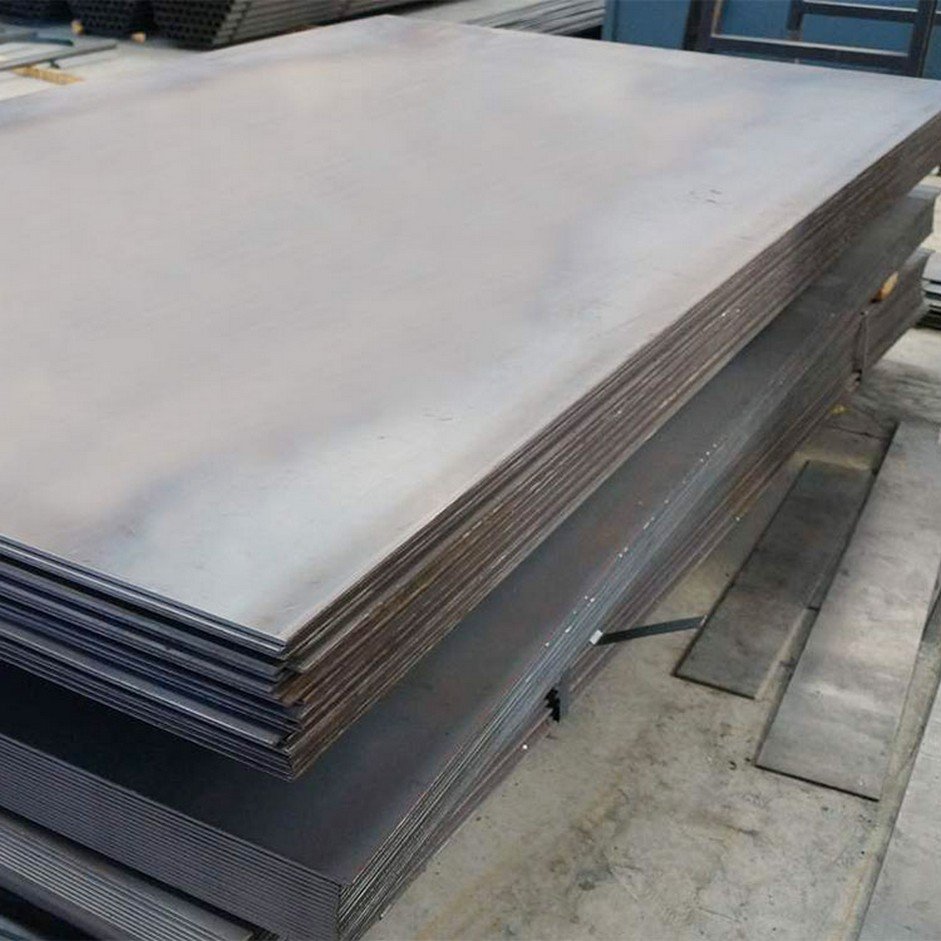

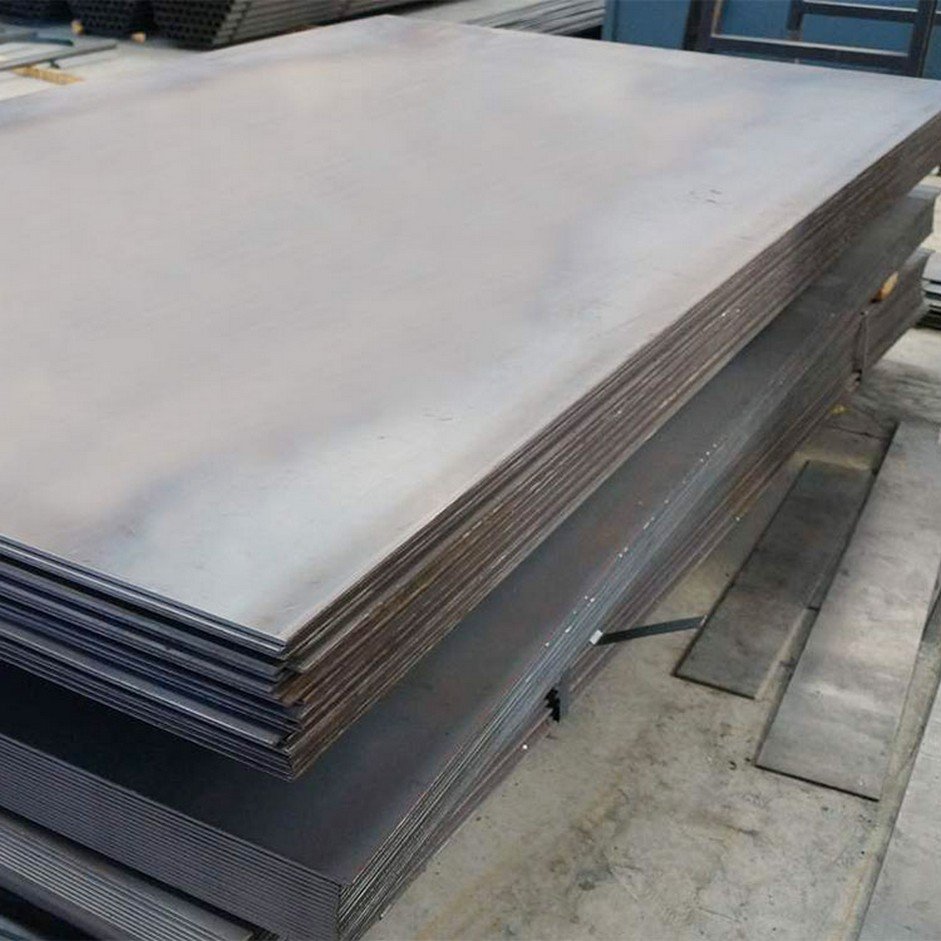

Cold Rolled Low Carbon Steel Hardness

Abstract:

This article aims to provide an in-depth analysis of cold rolled low carbon steel hardness. By delving into this topic, readers will gain a comprehensive understanding of the hardness properties of this specific type of steel. First, the article will introduce the concept of cold rolled low carbon steel hardness, providing essential background information. Then, it will explore the subject from four different aspects: microstructure, mechanical properties, heat treatment, and applications. Each aspect will be discussed thoroughly, presenting various viewpoints and supporting evidence. Finally, the article will summarize the main ideas and conclusions, emphasizing the importance of understanding cold rolled low carbon steel hardness and suggesting potential future research directions.

1. Microstructure

1.1 Cold Rolling Process and its Effect on Microstructure

The microstructure of cold rolled low carbon steel plays a crucial role in determining its hardness. In this section, we will explore how the cold rolling process influences the grain structure and dislocation density of the steel. Additionally, we will discuss the relationship between microstructure and hardness, highlighting the factors that contribute to increased hardness.

1.2 Phase Transformation and Structure-Property Relationship

Phase transformation is another vital aspect that affects the hardness of cold rolled low carbon steel. By examining the different phases involved, including ferrite, pearlite, and cementite, we can better understand the relationship between their distribution and hardness. Furthermore, we will discuss the influence of carbon content and alloying elements on the microstructure and hardness of this type of steel.

1.3 Texture and Anisotropy

The texture of cold rolled low carbon steel is a crucial factor that influences its mechanical properties, including hardness. We will explore the texture formation process during cold rolling and its impact on the anisotropic nature of the steel. Understanding the relationship between texture and hardness will provide valuable insights for optimizing the properties of this material in different applications.

2. Mechanical Properties

2.1 Hardness Testing Methods

Accurate measurement of hardness is essential for characterizing the properties of cold rolled low carbon steel. In this section, we will examine common hardness testing methods, such as Rockwell, Brinell, and Vickers hardness tests. We will discuss the principles, advantages, and limitations of each method, enabling readers to choose the most appropriate method for their specific requirements.

2.2 Factors Affecting Hardness

Various factors influence the hardness of cold rolled low carbon steel. In this subsection, we will delve into parameters such as carbon content, alloying elements, and processing conditions, discussing their effects on the mechanical properties and hardness of the steel. By understanding these factors, manufacturers can optimize the material properties to meet specific application needs.

2.3 Relationship Between Hardness and Other Mechanical Properties

Hardness is closely related to other mechanical properties, such as strength, toughness, and ductility. This section will explore these relationships, highlighting the trade-offs that exist in material design. We will discuss how variations in hardness affect the overall performance of cold rolled low carbon steel in different applications.

3. Heat Treatment

3.1 Annealing Process and its Effect on Hardness

Heat treatment, specifically annealing, is an essential process for controlling the hardness of cold rolled low carbon steel. We will discuss the annealing process, its effects on microstructure and hardness, and the factors that influence the success of annealing. Furthermore, we will explore the various annealing techniques used to achieve desired hardness properties.

3.2 Quenching and Tempering

Quenching and tempering are other heat treatment methods commonly employed to enhance the hardness of low carbon steel. This section will analyze the effects of these processes on the microstructure and mechanical properties of the steel. We will also discuss the importance of selecting appropriate quenching and tempering conditions to achieve the desired hardness level.

3.3 Case Studies of Heat Treatment and Hardness

To illustrate the practical applications of heat treatment on cold rolled low carbon steel hardness, this subsection will present case studies. We will examine real-world examples of how different heat treatment processes have been used to enhance the hardness properties for specific applications, highlighting the successes and challenges faced in each case.

4. Applications

4.1 Automotive Industry

The automotive industry heavily relies on cold rolled low carbon steel due to its desirable properties, including hardness. In this section, we will explore the specific applications of this type of steel in automotive components, such as body panels, chassis, and drivetrain parts. We will discuss how the  hardness requirements vary across different applications and the challenges faced in achieving the desired hardness levels.

hardness requirements vary across different applications and the challenges faced in achieving the desired hardness levels.

4.2 Construction Sector

Cold rolled low carbon steel finds extensive use in the construction sector, primarily due to its hardness and strength. This subsection will focus on its applications in structural elements, such as beams, columns, and reinforcing bars. We will discuss the specific hardness requirements in construction and how cold rolled low carbon steel meets those demands.

4.3 Machinery and Equipment

The hardness properties of cold rolled low carbon steel make it suitable for various machinery and equipment applications. This section will explore its usage in manufacturing machinery, agricultural equipment, and industrial tools. We will highlight the importance of hardness in improving wear resistance and extending the service life of these components.

V. Conclusion:

In conclusion, cold rolled low carbon steel hardness is a crucial factor that influences its mechanical properties and suitability for different applications. By understanding the microstructure, mechanical properties, heat treatment, and applications of this type of steel, manufacturers and engineers can optimize its properties to meet specific requirements. Furthermore, ongoing research is necessary to uncover new insights and develop innovative approaches to enhance the hardness properties of cold rolled low carbon steel. Overall, a comprehensive understanding of this topic is essential for the advancement of materials science and the successful implementation of cold rolled low carbon steel in various industries.