2023-11-09 01:40:10

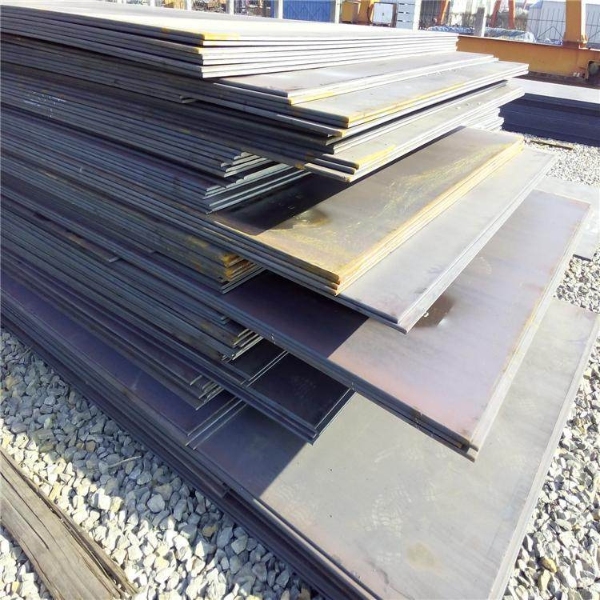

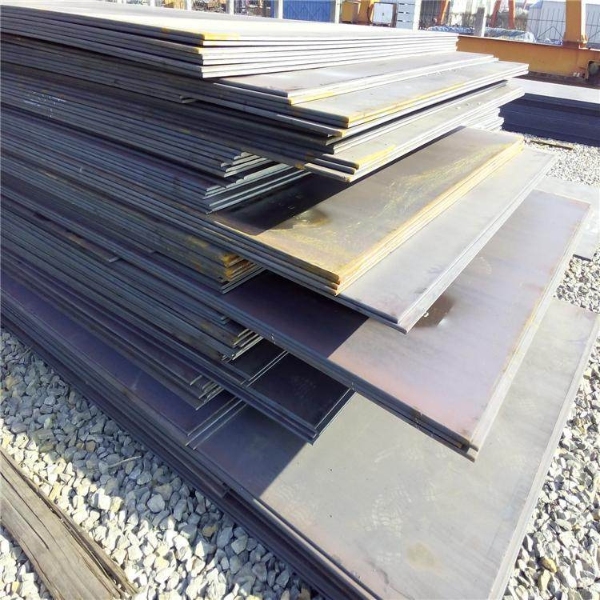

Finish Rolled Rebar Rusty: A Comprehensive Analysis

Abstract:

Rolling is a common method used in the manufacturing of reinforcing bars (rebar) used in construction projects. However, in some cases, finish rolled rebar may exhibit signs of rusting, which can have significant implications for the integrity and longevity of structures. This article aims to explore the phenomenon of finish rolled rebar rusting, providing readers with an understanding of its causes, consequences, and potential preventive measures.

Text:

1. Causes of Finish Rolled Rebar Rusty

1.1 Surface Contamination

Finish rolled rebar may become contaminated during the manufacturing process or when stored improperly. This contamination can include dirt, oil, or other substances that create an ideal environment for rust formation. Additionally, the chemicals used in the rolling process can also contribute to the corrosion of the rebar's surface.

1.2 Exposure to Moisture

Moisture is a primary catalyst for the corrosion of steel, including finish rolled rebar. If the rebar is exposed to rain, humidity, or standing water during storage or construction, the moisture can penetrate its protective layer, leading to the development of rust. Factors such as poor drainage or inadequate protection can exacerbate this issue.

1.3 Incorrect Handling and Storage

Improper handling and storage of finish rolled rebar can also contribute to its rusting. Excessive handling, mishandling, or exposure to abrasive materials during transportation can damage the rebar's surface, compromising its protective coating. Additionally, storing rebar in damp or moist environments increases the likelihood of rust formation.

2. Consequences of Finish Rolled Rebar Rusty

2.1 Structural Integrity

Rusting of finish rolled rebar can compromise the structural integrity of a building or infrastructure. As rust develops, the rebar loses its strength and load-bearing capacity, significantly increasing the risk of structural failure. This poses a severe threat to the safety of occupants and can lead to costly repairs or even collapse.

2.2 Aesthetics and Maintenance

In addition to the potential structural damage, rusty finish rolled rebar can negatively impact the aesthetic appeal of a structure. Rust stains and discoloration are unsightly and can diminish the overall appearance of a building, particularly in architectural designs where rebar is intentionally exposed. Moreover, regular maintenance and remediation efforts are necessary to mitigate the effects of rust and prevent further damage.

2.3 Economic Implications

The consequences of finish rolled rebar rusting extend beyond structural safety and aesthetics. The financial implications of compromised rebar can be substantial. Costs related to repairs, reinforcement replacement, and remediation efforts can significantly impact project budgets. Additionally, delays caused by addressing rusty rebar issues can lead to construction delays, contract disputes, and increased expenses.

3. Preventive Measures for Finish Rolled Rebar Rusty

3.1 Proper Storage and Handling

To prevent finish rolled rebar from rusting, it is crucial to implement appropriate storage and handling practices. This includes storing rebar in dry, well-ventilated areas with adequate protection against moisture. Utilizing protective coverings, such as tarps or plastic wraps, can minimize exposure to environmental factors and ensure the longevity of the rebar's protective coating.

3.2 Adequate Surface Preparation

Before using finish rolled rebar, proper surface preparation should be undertaken. This involves removing any surface contaminants, such as dirt or oil, and applying a high-quality anti-corrosion coating. Various coating methods, including epoxy or zinc-rich paints, can provide a protective barrier that effectively prevents rust formation.

3.3 Regular Inspection and Maintenance

Regular inspection and maintenance play a crucial role in identifying early signs of rusting and addressing them promptly. Implementing inspection protocols to monitor rebar conditions and scheduling routine maintenance activities, such as cleaning and reapplication of protective coatings, can significantly  extend the lifespan of finish rolled rebar and reduce the risk of rust-related issues.

extend the lifespan of finish rolled rebar and reduce the risk of rust-related issues.

Conclusion:

Finish rolled rebar rusty poses a substantial concern for the construction industry. The causes of rust formation on finish rolled rebar are multifaceted, including surface contamination, exposure to moisture, and incorrect handling and storage. The consequences range from compromised structural integrity to aesthetic defects and economic implications. However, preventive measures such as proper storage and handling, surface preparation, and regular maintenance can effectively mitigate these risks. By implementing these measures, the construction industry can ensure the longevity and safety of structures, minimizing the impact of finish rolled rebar rusty. It is essential for manufacturers, contractors, and engineers to prioritize understanding and addressing this issue to uphold the highest standards of construction quality.