2023-10-22 17:08:06

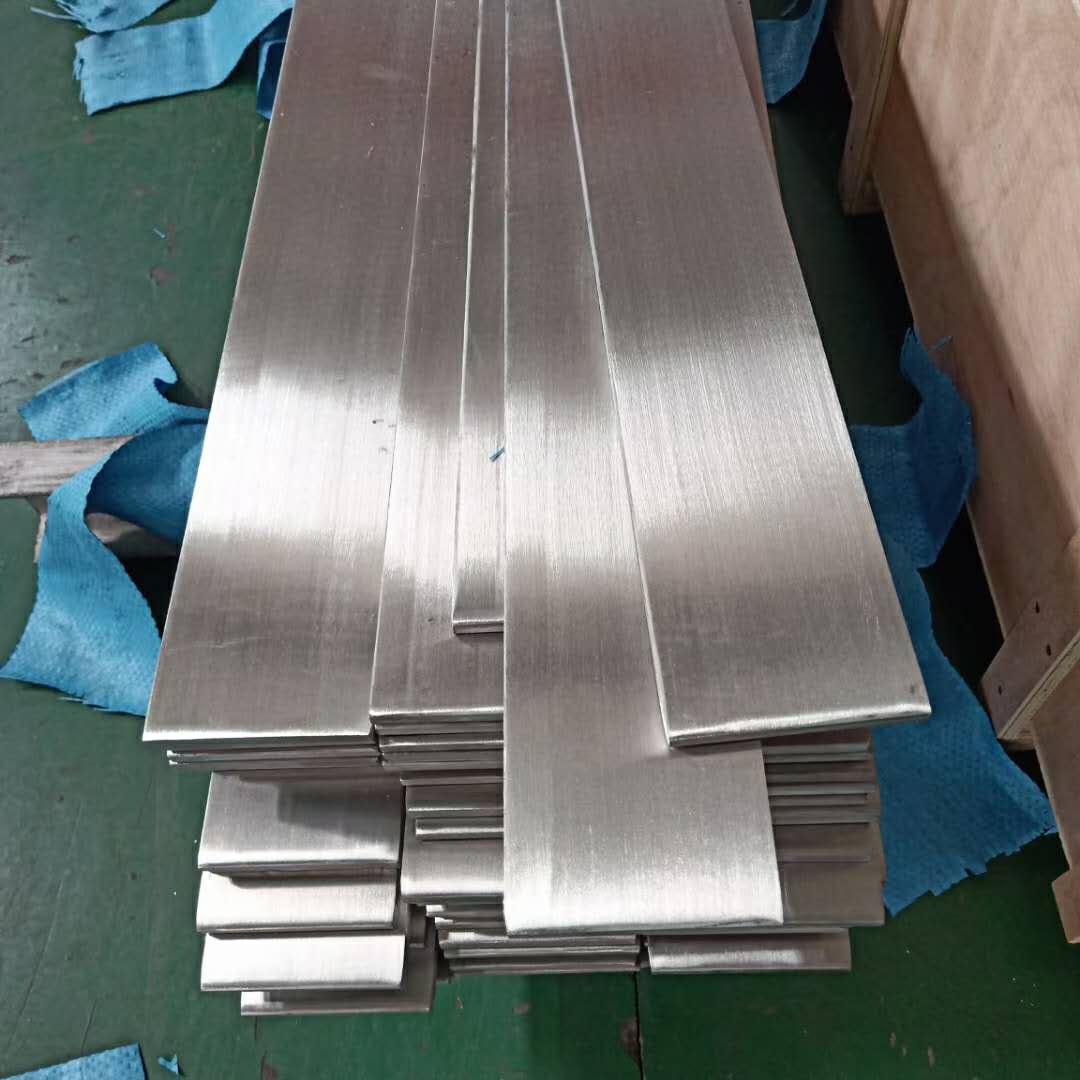

Tensile Carbon Steel Mold Material

Abstract:

This article introduces Tensile carbon steel mold material, providing background information and arousing readers' interest. Tensile carbon steel mold material is a vital component in mold production, and understanding its properties and applications can greatly benefit the manufacturing industry.

Text:

1. Introduction to Tensile Carbon Steel Mold Material

Tensile carbon steel mold material is a type of steel that exhibits high strength and excellent ductility. It is widely used in various industries, including automotive, aerospace, and electronics, where molds are essential for production. Tensile carbon steel mold material offers several advantages, such as its ability to withstand high temperatures and resist wear and tear. This section will delve deeper into the properties and characteristics of this material.

2. Properties and Characteristics of Tensile Carbon Steel Mold Material

2.1 Strength:

Tensile carbon steel mold material demonstrates exceptional strength, making it suitable for withstanding the high pressures and forces exerted during the mold production process. Its tensile strength ensures the durability and longevity of the molds, reducing the need for frequent replacements or repairs.

2.2 Ductility:

One of the standout features of tensile carbon steel mold material is its excellent ductility. This property allows the material to be easily shaped and formed into complex mold designs, ensuring precision and accuracy in the manufacturing process. The combination of strength and ductility makes it an ideal choice for producing intricate molds that require high precision.

2.3 Heat Resistance:

Tensile carbon steel mold material exhibits remarkable heat resistance, enabling it to withstand elevated temperatures without compromising its structural integrity. This characteristic is crucial in applications where molds are subjected to extreme heat, such as in the plastic injection molding process. The material's ability to resist thermal expansion and maintain its dimensional stability is essential to ensure the quality of the end products.

2.4 Wear Resistance:

In the manufacturing industry, molds can be subjected to substantial wear and tear due to repeated use. Tensile carbon steel mold material possesses excellent wear resistance, ensuring its longevity and reducing the need for frequent replacements. This property significantly reduces production downtime and maintenance costs, making it a cost-effective choice for mold production.

3. Applications of Tensile Carbon Steel Mold Material

3.1 Automotive Industry:

The automotive industry extensively utilizes Tensile carbon steel mold material for various components, including body panels, engine parts, and interior trims. Its strength,  ductility, and heat resistance properties make it an ideal choice for producing high-quality molds used in mass production processes.

ductility, and heat resistance properties make it an ideal choice for producing high-quality molds used in mass production processes.

3.2 Aerospace Industry:

In the aerospace industry, where precision and reliability are of utmost importance, Tensile carbon steel mold material finds broad applications. From manufacturing complex engine parts to producing structural components, this material ensures the production of molds that can withstand extreme conditions and maintain dimensional accuracy.

3.3 Electronics Industry:

The electronics industry demands molds that can produce intricate and delicate components with exceptional precision. Tensile carbon steel mold material's ability to be easily shaped and its wear resistance properties make it an excellent choice for producing molds used in the manufacturing of electronic devices.

4. Future Developments and Research Directions

As the manufacturing industry continues to evolve, there is a constant need for innovative materials and technologies in mold production. Future research should focus on further enhancing the performance of Tensile carbon steel mold material. Areas of interest include improving its high-temperature resistance, developing new alloy compositions to enhance specific properties, and exploring advanced manufacturing techniques for producing molds with greater precision.

Conclusion:

Tensile carbon steel mold material plays a crucial role in the manufacturing industry, offering exceptional strength, ductility, heat resistance, and wear resistance. Its applications in diverse industries highlight its significance in mold production. Continual research and development in this field will contribute to the advancement of materials and technologies for mold production, ultimately benefiting various industries worldwide.