2023-10-21 17:38:35

Billet carbon steel is a type of carbon steel that is widely used in various industries due to its excellent mechanical properties and versatility. This article aims to provide a comprehensive understanding of billet carbon steel by exploring its characteristics, manufacturing process, applications, and future developments. By delving into these aspects, readers will gain valuable insights into the fascinating world of billet carbon steel and its significance in modern society.

Billet carbon steel possesses a unique set of characteristics that sets it apart from other types of steel. Firstly, it is primarily composed of iron and carbon, with the carbon content ranging from 0.3% to 0.5%. This carbon content imparts exceptional strength and hardness to the steel, making it suitable for heavy-duty applications. Additionally, billet carbon steel exhibits excellent machinability, weldability, and formability, allowing it to be easily shaped into desired forms. Furthermore, its high thermal conductivity and electrical resistivity make it ideal for applications in the electrical and heat transfer industries.

The microstructure of billet carbon steel is also noteworthy. It typically consists of ferrite and pearlite phases, which contribute to its mechanical properties. The presence of pearlite, a lamellar mixture of ferrite and cementite, enhances the steel's strength without compromising its ductility. Furthermore, the microstructure can be modified through heat treatment processes, such as quenching and tempering, to further enhance the material's mechanical properties.

The manufacturing process of billet carbon steel involves several steps, each crucial in determining the final quality of the product. It begins with the sourcing of raw materials, where iron ore, coal, and limestone are smelted in a blast furnace to produce pig iron. The pig iron is then further refined through the basic oxygen steelmaking or electric arc furnace processes to reduce impurities and achieve the desired carbon content.

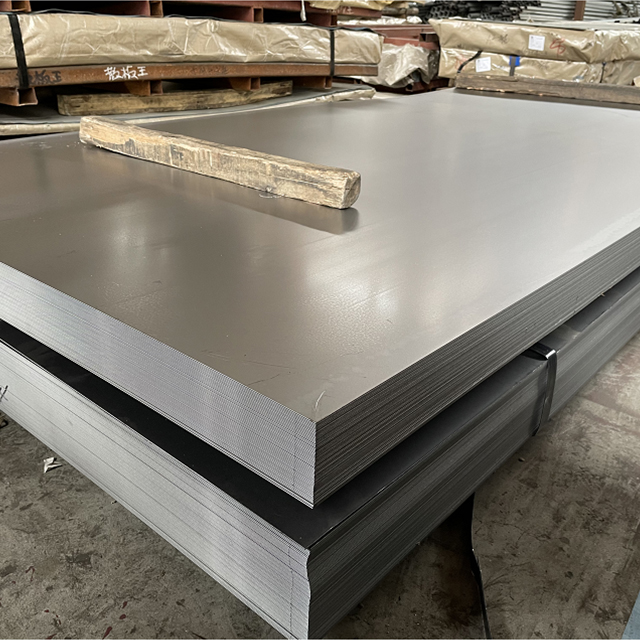

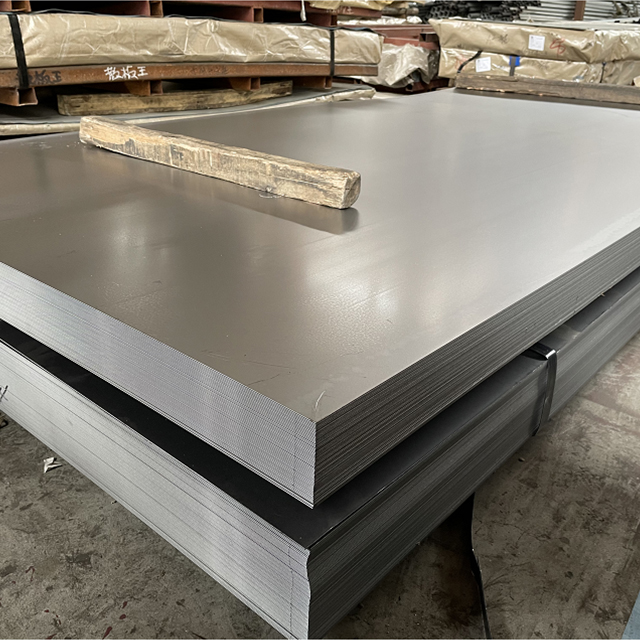

After refining, the molten steel is cast into billet form through either continuous casting or ingot casting. Continuous casting is a widely adopted method that ensures a uniform microstructure and excellent surface quality. In contrast, ingot casting involves pouring the molten steel into molds, followed by solidification and subsequent removal of the ingots for further processing.

Subsequently,  the billets undergo hot rolling, a process that involves passing them through a series of rolling mills to obtain the desired dimensions and shape. Cold rolling may also be employed to achieve precise dimensional tolerances, improved surface finish, and increased strength.

the billets undergo hot rolling, a process that involves passing them through a series of rolling mills to obtain the desired dimensions and shape. Cold rolling may also be employed to achieve precise dimensional tolerances, improved surface finish, and increased strength.

Billet carbon steel finds extensive applications across various industries. In the construction industry, it is used for the fabrication of structural components, such as beams, columns, and rods, due to its high strength and load-bearing capacity. Additionally, billet carbon steel is widely utilized in the automotive industry for the production of chassis components, engine parts, and suspension systems, owing to its excellent mechanical properties and impact resistance.

Furthermore, billet carbon steel plays a crucial role in the manufacturing of pipes, tubes, and fittings for the oil and gas industry. Its corrosion resistance and durability make it an ideal choice for withstanding harsh environmental conditions. Moreover, the electrical industry relies on billet carbon steel for the production of conductors, transformers, motors, and generators due to its high electrical conductivity.

The future of billet carbon steel is characterized by continuous improvements in its mechanical properties, sustainability, and manufacturing processes. Research efforts are focused on enhancing strength, toughness, and corrosion resistance through alloying elements and advanced heat treatment techniques. Additionally, there is a growing interest in developing environmentally friendly manufacturing processes to reduce carbon emissions and energy consumption.

However, challenges remain in the form of cost optimization and environmental impact. The fluctuation in raw material prices and the high energy consumption during production pose challenges to the widespread adoption of billet carbon steel. Addressing these issues requires collaborative efforts from stakeholders across the industry to develop innovative solutions and explore alternative materials and processes.

Billet carbon steel is a versatile and indispensable material in various industries due to its exceptional mechanical properties and wide range of applications. It possesses unique characteristics, including high strength, machinability, and formability, making it suitable for demanding applications. The manufacturing process of billet carbon steel involves several steps, from refining raw materials to casting and rolling. The future of billet carbon steel lies in continuous advancements in alloying, heat treatment, and sustainable manufacturing processes. By understanding the characteristics and applications of billet carbon steel, we can appreciate its significance in modern society and contribute to its further development.