2023-10-14 02:25:45

Abstract:

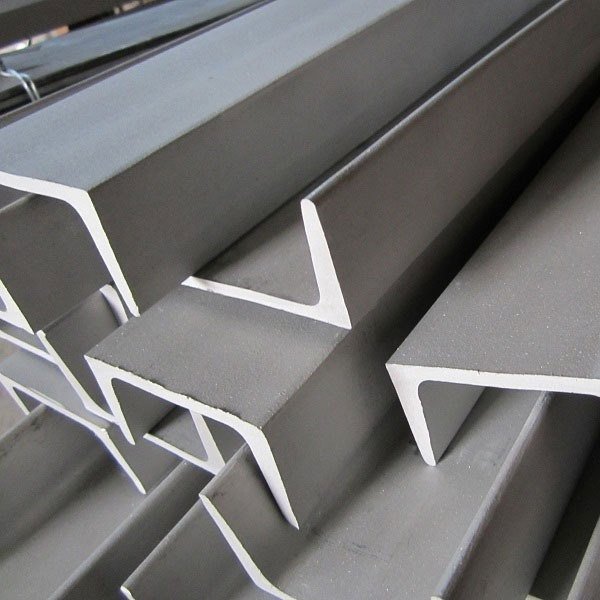

Is the finish-rolled rebar hot-rolled or cold-rolled? This article aims to explore and provide detailed information on this subject. The use of rebar, or reinforcement bar, is critical in construction projects to enhance the strength and durability of concrete structures. Understanding the manufacturing process of rebar, specifically the finish-rolling method, is essential for ensuring the quality and performance of the final product. By examining the differences between hot-rolled and cold-rolled finish-rolled rebar, this article will shed light on the various aspects associated with this topic.

Keywords: finish-rolled rebar, hot-rolled, cold-rolled, manufacturing process, construction

1. Manufacturing Process:

Rebar undergoes a complex manufacturing process before reaching its final form. The first aspect to explore is the manufacturing process of finish-rolled rebar. This section will discuss the general steps involved, including the heating, rolling, and cooling processes. The use of high-strength steel and the impact on the final product's properties will also be explored. Furthermore, the differences in the manufacturing process between hot-rolled and cold-rolled rebar will be analyzed in detail.

1.1 Heating Process:

The heating process plays a crucial role in the manufacturing of finish-rolled rebar. This paragraph will describe the techniques used to heat the steel billets, such as the use of furnace or induction heating. It will also discuss the temperature ranges required for hot-rolled and cold-rolled rebar and the impact of these temperatures on the final product's mechanical properties. The heating process is a critical step that affects the subsequent rolling and cooling processes.

1.2 Rolling Process:

The rolling process is where the steel billets are transformed into finish-rolled rebar. This section will delve into the differences between hot-rolled and cold-rolled rebar during the rolling process. The impact of temperature, pressure, and speed on the formation of grain structure and strength will be analyzed. The role of different rolling mills, such as continuous or semi-continuous mills, will also be discussed. Understanding the nuances of the rolling process is essential for determining if the finish-rolled rebar is hot-rolled or cold-rolled.

1.3 Cooling Process:

After the rolling  process, the rebar needs to be properly cooled to obtain the desired mechanical properties. This paragraph will explain the cooling process for finish-rolled rebar. It will discuss the various cooling methods used, including natural cooling or forced air/water cooling. The impact of cooling rate on the formation of microstructures and the resulting mechanical properties will be examined. The differences in cooling methods between hot-rolled and cold-rolled rebar will be highlighted.

process, the rebar needs to be properly cooled to obtain the desired mechanical properties. This paragraph will explain the cooling process for finish-rolled rebar. It will discuss the various cooling methods used, including natural cooling or forced air/water cooling. The impact of cooling rate on the formation of microstructures and the resulting mechanical properties will be examined. The differences in cooling methods between hot-rolled and cold-rolled rebar will be highlighted.

2. Mechanical Properties:

The next aspect to consider is the mechanical properties of finish-rolled rebar, specifically the differences between hot-rolled and cold-rolled rebar. This section will discuss the factors that influence the mechanical properties, such as tensile strength, yield strength, and elongation. The effects of grain structure and microstructural changes on the mechanical properties will also be explored. Understanding these differences is crucial for selecting the appropriate rebar for specific construction projects.

2.1 Tensile Strength:

Tensile strength is a key parameter to assess the quality and performance of rebar. This paragraph will explain the concept of tensile strength and its significance in construction applications. It will discuss the factors that affect the tensile strength of finish-rolled rebar, such as the type of rolling process, grain structure, and cooling rate. The differences in tensile strength between hot-rolled and cold-rolled rebar will be examined, including the implications for different construction scenarios.

2.2 Yield Strength:

Yield strength is another important mechanical property that determines the structural integrity of rebar. This section will define yield strength and its relevance to construction projects. It will analyze the factors that influence the yield strength of finish-rolled rebar, including the manufacturing process and the resulting microstructural changes. A comparison between hot-rolled and cold-rolled rebar regarding yield strength will be provided, highlighting the advantages and limitations of each.

2.3 Elongation:

Elongation is a measure of a material's ability to elongate or deform before reaching its breaking point. This paragraph will discuss the significance of elongation in rebar applications, as it reflects the ductility and flexibility of the material. It will delve into the factors that impact the elongation of finish-rolled rebar, such as the rolling process and microstructural characteristics. The distinctive elongation properties of hot-rolled and cold-rolled rebar will be explored, enabling a better understanding of their suitability for different construction needs.

2.4 Other Mechanical Properties:

Apart from tensile strength, yield strength, and elongation, there are other mechanical properties that differentiate hot-rolled and cold-rolled rebar. This section will briefly touch upon these properties, such as modulus of elasticity, impact strength, and fatigue resistance. The influence of the manufacturing process on these properties will be discussed, providing insights into the overall performance of finish-rolled rebar in construction applications.

3. Quality Control and Standards:

Ensuring the quality and compliance of finish-rolled rebar with industry standards is crucial for construction projects' success. This section will discuss the quality control measures employed during the manufacturing process. It will highlight the internationally recognized standards, such as ASTM and ISO, that govern the production and testing of rebar. The role of quality certifications and third-party testing will also be explored in this context. Understanding the quality control processes and standards is vital for selecting reliable and high-quality finish-rolled rebar.

4. Conclusion:

In conclusion, the manufacturing process and mechanical properties of finish-rolled rebar have significant implications for construction projects. Differentiating between hot-rolled and cold-rolled rebar is essential for ensuring the appropriate selection and use of rebar based on specific project requirements. By comprehensively exploring the manufacturing processes, mechanical properties, and quality control measures, stakeholders in the construction industry can make informed decisions and enhance the overall quality and durability of concrete structures. Further research and development in this field can contribute to better understanding and utilization of finish-rolled rebar in construction applications.